Ring Dex Models

The Ring Dex system provides a unique solution for streamlining your manual filling, tipping, capping and assembly operations with one precise and affordable package.

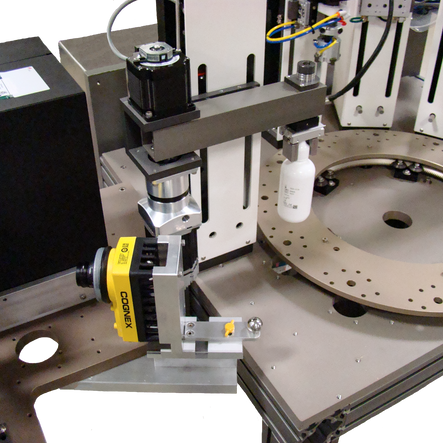

The Ring Dex machine consists of powered work stations mounted around a centrally located indexing ring. Each work station is self-contained and provides true multi-tasking & real time performance. This filling and capping system is menu driven and is controlled by the front panel touch pad. A bar code scanner input is included as well.

The Ring Dex dials are removable for quick changeover requiring no previous technical experience. Great for processing families of small bottles and vials. Most times changeover means just loading a new file.

Latest Control System Technology

Better Fill Control

Fill files control the peristaltic (or positive displacement) pump with simple graphical menu entry.

-

Fill Volume / Fill Speed

-

Position

-

Diving Nozzle (Servo) Programmable

-

Snuff-back Control

-

Additional Logic

Capping Torque & Pitch

Cap files control the station with simple, graphical menu entry of pre-programmed servo parameters.

-

Bottle Height

-

Cap Thread Data

-

RPM & Number of Turns

-

Programmable Torque

Check Fill Volumes

Scale files record each bottle’s pre and post weight with ultra-precision and are settable in: ounces, grams, etc.

-

Set Ideal Weight

-

Set Acceptable Range

-

Provide Logic for Over Weight

-

Provide Logic for Under Weight

On Board Pump Calibration

Just enter the actual weight from a sample. Automatically adjusts all encoder values. A limitless number of pump files may exist in the machine for different tubing sizes, nozzles, etc. Ideal for future expansion.

Project Gallery

BENCH TOP

Ring Dex Available with Bar Code Reader

To Scan Work Orders for Job Selection

OPTIONS AVAILABLE

Ring Dex Shown with Optional Scaleand Accumulator Dial

QUICK CHANGE OVER

Ring Dex Bench Top

Filling and Capping System

MULTIPLE BOTTLES

Modular Mono Block Design Allows Work Stations to be Configured As Needed